Service Support

Service hotline:

400-888-2236

Experience in the vacuum industry

15+year

Senior sales team

300+

Supporting enterprise services

1600+

LDVAC has 15 years of experience in the vacuum industry and a professional R&D and production team! We provide customers with high-quality and highly reliable vacuum technology solutions in fields such as laboratory instruments, lithium batteries, electricity, new materials, solar energy, photovoltaics, semiconductors, surface coatings, chemical research and applications!

Factory image

Machining center

Detection equipment

PRODCUTS

Rotary vane vacuum pump

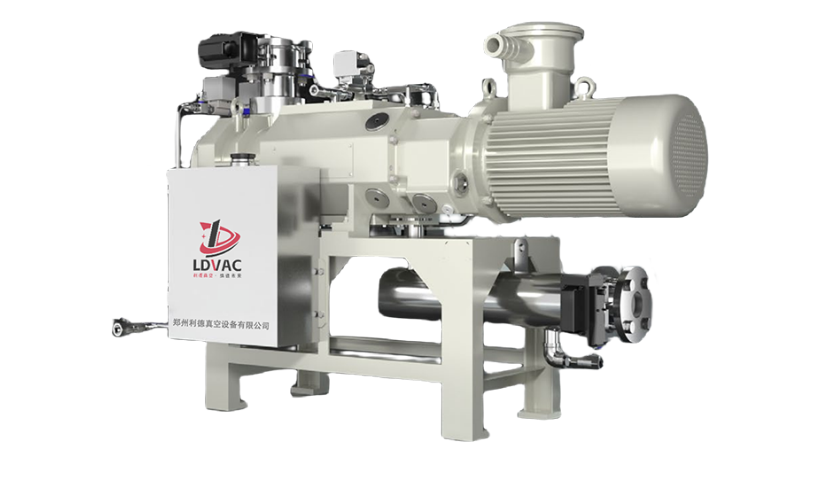

Screw Roots vacuum pump

Vacuum unit

Double stage rotary vane vacuum pump

The unique design of Lide's dual anti return oil structure and automatic anti return oil valve effectively avoid and solve the problem of oil return in emergency situations, so that your equipment will not be contaminated due to oil return

Forced lubrication, built-in gear pump and constant pressure oil supply mechanism for forced oil supply, stable and reliable operation even under high suction pressure

Multi level pneumatic design to meet customers' vacuum requirements and water vapor processing capabilities.

5X10-2Pa

High limit vacuum

≤52dB

Low noise, quieter

7X24 hours

Continuous work

≤40℃

Pump temperature rise

Dry screw vacuum pump

The pump chamber of the dry screw vacuum pump is equipped with a pair of multi-stage spiral rotors that rotate synchronously in reverse meshing, dividing the pump chamber into several disconnected cavities. During normal operation, with the meshing rotation of the two rotors, a suction chamber is generated and the volume continuously increases to suck in gas. When the volume reaches its maximum, the suction chamber becomes an intermediate chamber; The middle chamber moves to the right to transport gas from the intake end to the exhaust end. When the middle chamber is connected to the exhaust port channel, the middle chamber becomes the exhaust chamber, and the volume of the exhaust chamber decreases to discharge gas. After all the gas is discharged, the next middle chamber begins to be connected to the exhaust channel. This cycle repeats itself to form a continuous pumping effect.

1Pa

Extreme vacuum

1080m3

Large extraction volume

0 Pollution

Dry operation

7X24 hours

Continuous work

Dry vacuum unit

Chemical industry: Dry vacuum pump units are widely used in the chemical industry for processes such as gas extraction, distillation, drying, and transportation

Electronics industry: Dry vacuum pump units can provide a clean and dust-free environment in the electronic manufacturing process, suitable for key links such as semiconductor manufacturing and display production

Research laboratory: Dry vacuum pump units are widely used in the field of scientific research, and can be used for vacuuming vacuum chambers and experimental equipment, as well as manufacturing relatively stable experimental environments

Medical industry: Dry vacuum pump units are commonly used in medical equipment for suction and delivery of gases, such as suction systems, artificial ventilators, etc

Vacuum heat treatment: Dry vacuum pump units are used in the metal processing industry for processes such as vacuum furnaces and vacuum heat treatment, and can provide high-quality metal products

Oil free and pollution-free

Energy conservation and environmental protection

Stable and reliable operation

Easy and convenient maintenance

Service support

After sales support

(1) The warranty period is one year from the date of purchase

(2) During the warranty period, if any malfunction occurs under normal usage conditions as required by the user manual, our company will provide free repair services

(3) Malfunctions caused by the following situations require paid repairs by our company:

·Malfunctions caused by natural disasters or human factors ·Damage to vulnerable parts ·Malfunctions caused by use in special environments ·According to the appraisal of our technical personnel, the malfunction was caused by illegal operation.

Contact Hotline: